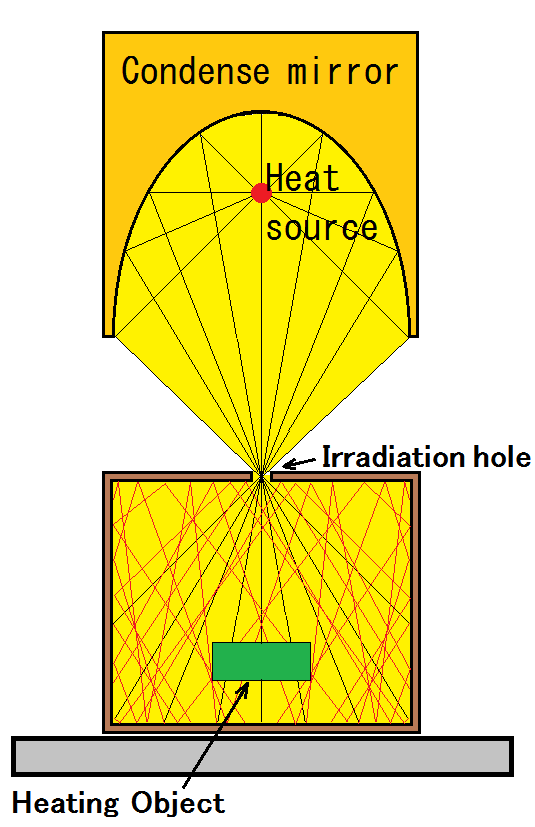

Basic principle

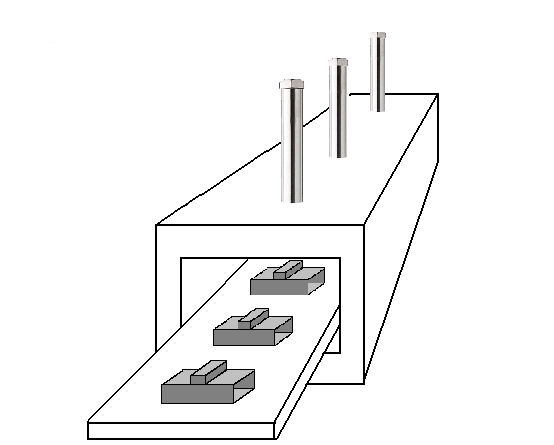

Make a small hole in the box and heat it from the outside.

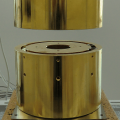

Using this heating method, you can also create a high-temperature electric furnace with a simple structure.

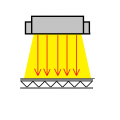

Assuming that the inner surface of the box has a reflectance of 100%, all of the light energy input from the irradiation hole will be reflected in places other than the irradiation hole.

The only object that absorbs this light energy is the object inside the box, so if all the light could be absorbed and converted into thermal energy, the heating limit could reach approximately 1800℃.

This is a method that can uniformly heat objects with poor infrared absorption, relatively large objects, and dispersed objects to a high temperature with high efficiency.

The key to the success of this heating method is all about creating a highly reflective box.

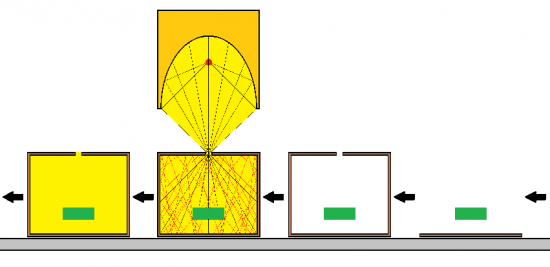

Unlike the common “furnace”, the heat source and the box can be separated, so they can be used inline on the belt conveyor.

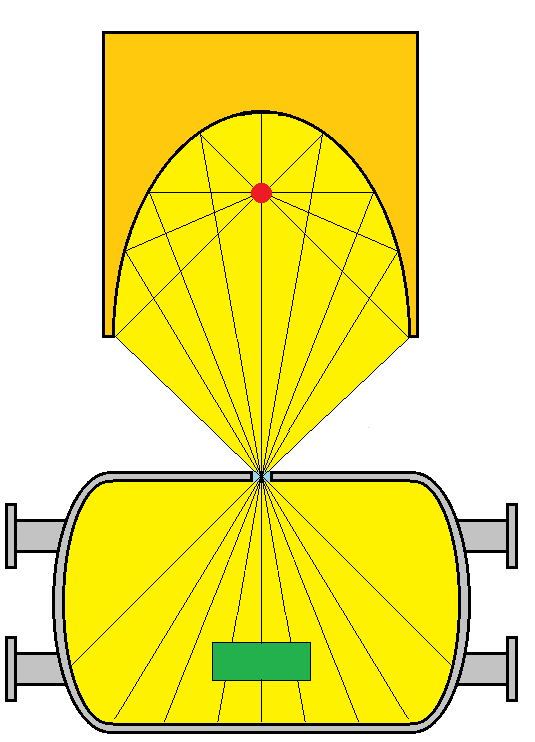

Box heating can also be a two-piece structure in which the object to be heated can be taken in and out.

In addition, the shape of the box can be any shape such as a triangle, a sphere or a cylinder, as well as a square as shown in the figure.

The inside wall of the box is ideally a mirror surface with a high reflectance like gold plating, but smoke may be generated from the object to be heated, and a high mirror surface is difficult to maintain.

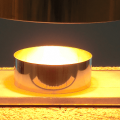

Heating the inside of the vacuum chamber

There is also a method of heating in a vacuum chamber using quartz glass for the irradiation hole.

Since the inside can be made non-oxidative atmosphere, non-oxidative heating processing becomes possible.

Or you can make some kind of chemical reaction in a special gas.

It is particularly convenient for electric furnaces that require cleanness.

Since there is no heating element inside the furnace, there is no contamination generated from the heating element, and the interior remains clean.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop