INDEX

비례 제어로 잘 제어 할 수 있도록 생각할 수 있지만 실제로는 현재 값이 설정 값에 도달하면 문제가 일어납니다.

그것은 조작량이 너무 작아, 더 세밀하게 제어 할 수없는 상태가 발생합니다.

그 결과, 설정 값에 매우 근접한 현재가 상태에서 안정된 상태로되어 버립니다.

이렇게되면 설정 값에 가까워은됩니다 만, 언제 까지나 설정에 딱해서는 안 상태가되어 버립니다.

이 약간의 오차를 「오프셋」이라고합니다.

오프셋 (Offset)은 설정 값과 현재 값의 작은 차이가 일정한 값으로 영구적으로 이어지는 것입니다.

간단하게 말하면 “위화감”입니다.

이 오프셋을 없애기 위해 사용되는 것이 적분 제어합니다.

즉, 약간의 차이를 시간적으로 누적 한 크기로 된 곳에서 조작량을 증가하여 차이 (오프셋)를 없애도록 작동시킵니다.

따라서, 비례 동작에 적분 동작을 추가 한 제어를 “PI 제어”라고합니다.

앞에서 설명했듯이, 비례 제어는 비례 대 내에서의 현재 값과 설정 값의 차이 (편차)에 비례 한 가열을 제어함으로써 비례의 기준은 제조사의 기본적으로 5 ~ 10 %로 설정되어 있습니다.

● 오프셋은 어떤 이유로 나타나는 것일까 요?

비례 제어는 설정 값 근처에서 안정성을 중시하여 가열 량이 너무 작아, 더 세밀하게 제어 할 수없는 상태가 발생합니다. 결과는 설정 값에 매우 근접한 현재 값에서 안정된 상태로되어 버립니다. 현상을 유지하고 말았 변화시킬만큼 열량에 도달하기 때문이다.

● 오프셋은 어떤 때 나타나는 것일까 요?

① 가열 대상이 너무 크거나 너무 작은 경우.

장치 및 시스템을 설계 한 조건에 비해 큰 부하를 넣은 경우, 부하에 의해 빼앗기는 열량이 증가 때문에, 설정 값보다 낮은 곳에서 안정합니다. 반대로 부하의 작은 물건을 넣을 경우는 그 반대가되어, 높은 곳에서 안정합니다.

② 장치의 주위 온도가 변화 한 경우

겨울철 등은 장치의 주위 온도가 낮고 빼앗기는 열량이 증가하므로 설정 값보다 낮은 오프셋이 나타나기 쉽다입니다. 반대로 여름철 등 주위 온도가 높고, 방열이 적기 때문에 높은 오프셋이 나타나기 쉽다입니다.

③ 설정 값을 변경 한 경우

예를 들면 500℃로 조정 한 가열로에서 500℃보다 높은 온도에서 사용하면 낮은 오프셋이 빠져 나가 500℃보다 낮게 설정하면 높은 오프셋이 나타나기 쉽다입니다.

● 내부에서는 어떤 일을하고있는 것일까 요?

첫째, 비례 제어만으로는 이론적으로 오프셋이 없어지지 않는다는 것이 전제가됩니다. 장시간 지나도 안정되어있는 현상을 생각하면 조절계에서 어떠한 출력 신호가 나오고있는 것은 분명하다. 그러나, 현재의 출력으로는 역부족 목표치까지 도달없이 안정되어 있다는 것입니다.

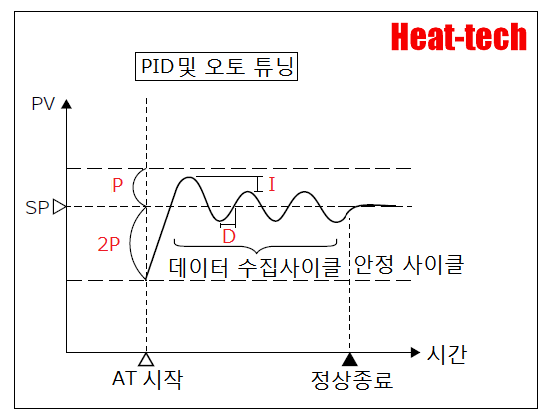

이 오프셋을 제로하기 위해서는 현재의 출력 신호에 어긋남을 수정하는 분을 더한 출력 신호를 내 줄 필요가 있습니다. 이것을내는 것이 적분 제어의 역할입니다. 적분 제어는 1. 과거의 편차를 축적하고 2 설정 시간의 범위에서 편차를 해소하는 것입니다.

현재 값 PV의 차이의 적분이 0으로 설정하여 설정 값 SV 온도에 도달 할 때까지 적분 제어는 비례 대를 원래 SV에서 높은 온도로 밀어 출력 오프셋을 제거합니다.

적분 시간이 너무 길면, 시간당 수정 양이 충분하지 않고, 언제 까지나 오프셋이 제거되지 않습니다.

적분 시간이 짧으면 수정이 강하게 걸리는하게되어 큰 수정 량이 짧은 시간에 일하고 편차를 신속하게 해결할 수 있습니다.

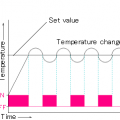

그러나 적분 시간을 짧게 설정 으면 헌팅이 일어나기 쉽고, 안정된 제어 결과이 필요 없게되므로주의가 필요합니다.

메이커 기본적으로 120 초이 많은 설정하는 기준으로는 100 ~ 150 초 정도입니다.

● 적분 (Integral) 제어는 설정 시간에서 오프셋을 제로로하기 위해 출력을 조절하는 수정 작업입니다.

적분 제어는 단독으로도 제어 능력이 있습니다. 따라서 I 동작 만 제어가 가능합니다. 그러나 PI 제어에 비해 크게 제어 응답이 나빠집니다.

아날로그 제어의 초기 시대에는 간단하고 싸게 할 수 있다는 점에서 I 동작 단독 제어가 사용 된 수 있습니다. 그러나 최근에는 사용되는 것은 거의 없습니다.

HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵