INDEX

- Memory card data folder function

- Multistep setting can be done easily by a touch panel display.

- Multistage setting function

- Gradient setting function

- Sine curve setting function

- One-Shot heating function

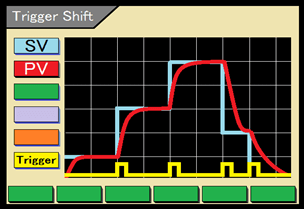

- Trigger Shift function (optional)

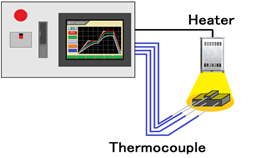

- From multiple sensors, can be heating test by setting any of the input to the reference temperature.

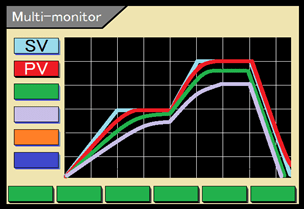

- Multi-monitor function

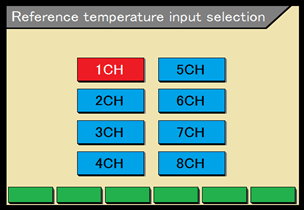

- Reference temperature input selection function

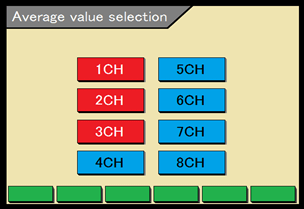

- Average value control function

- Multi-loop supervisor function built-in. That can cooperative control several heaters.

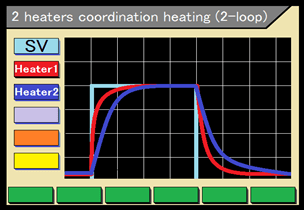

- 2 heater coordination heating function (2-loop)

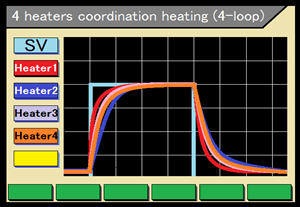

- 4 heater coordination heating function (4-loop)

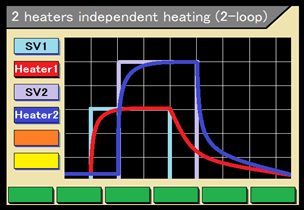

- 2 heater independent heating function (2-loop)

- Design Number List

Condition setting, confirmation and recording,

the heater controller of 3 function 1 equipment.

Profile-maker SSC series

Memory card data folder function

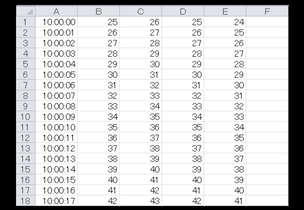

Read the heating data from the memory card, and can edit the tables and graphs in EXCEL.

Heating data can be taken out easily from a memory card slot in the panel surface.

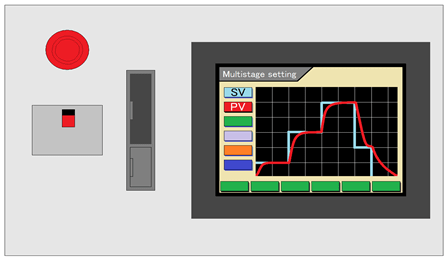

Multistep setting can be done easily by a touch panel display.

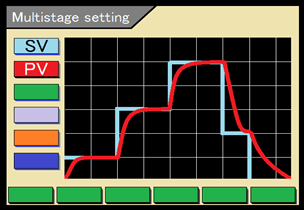

Multistage setting function

A processing method such as a decline of the surface tension by the heating and extinction of the residual stress can be considered.

Setting the reservoir of intermediate polymerization reaction.

Repeated heating and cooling method

Maintenance of solution processing temperature

Two-stage preheating quenching processing

Gas nitriding processing

Gas two-stage nitriding processing

Salt bath soft nitriding processing

Gas soft nitriding processing

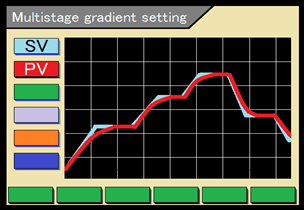

Gradient setting function

Important expansion and shrinkage rate, it is test for a precision material.

Trapezoidal control.

Isothermal annealing

Management of recrystallization temperature

Slow heat → annealing → slow cooling process

Two-stage annealing

Age hardening treatment

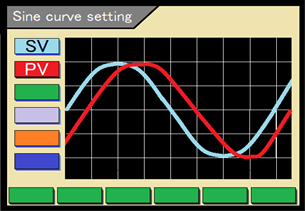

Sine curve setting function

Heat cycle test of an electronic device.

Aging accelerated test of an electronic device.

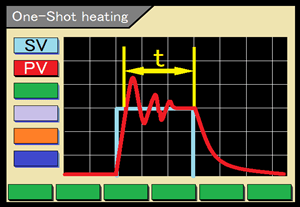

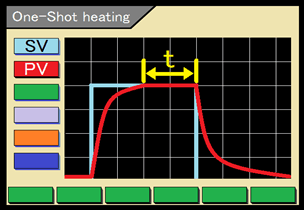

One-Shot heating function

The condition shortening of the tact time

The tempering time management

The normalizing time management

Trigger Shift function (optional)

When the trigger is input, and then move on to the next set temperature.

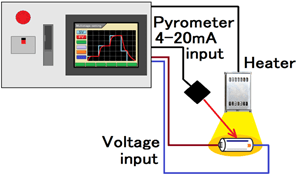

From multiple sensors, can be heating test by setting any of the input to the reference temperature.

Multi-monitor function

Temperature distribution can know in real time.

Reference temperature input selection function

The sensors can be multiple mounting, heating the any position on the reference or the best, can evaluate the mounting position.

Average value control function

The sensor can be multiple mounting, the heating evaluate the position of the virtual to the reference.

Multi-loop supervisor function built-in.

That can cooperative control several heaters.

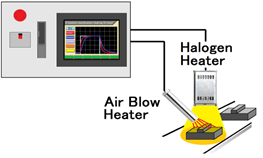

2 heater coordination heating function (2-loop)

Heat the one object, use the air blow heater and halogen heater.

4 heater coordination heating function (4-loop)

A certain areas is heated uniformly using 1 heater.

2 heater independent heating function (2-loop)

A certain areas is heated uniformly using several heaters.

Design Number List

| Design Number | Input Volt | Output | Power | Loop | Signal | dimensions |

|---|---|---|---|---|---|---|

| SSC-DC12V-300W-1L | AC85-264v | DC0~12v | 300w | 1Loop | Temp. input 4CH / Analog input 4CH | Standard |

| SSC-DC24V-300W-1L | AC85-264v | DC0~24v | 300w | 1Loop | Standard | |

| SSC-DC24V-600W-2L | AC85-264v | DC0~24v | 300w x2 | 2Loop | Standard | |

| SSC-DC36V-600W-1L | AC85-264v | DC0~36v | 600w | 1Loop | Standard | |

| SSC-DC36V-1200W-2L | AC85-264v | DC0~36v | 600w x2 | 2Loop | Standard | |

| SSC-AC15A-1L | AC100-110/200-220v | 15A | 1Loop | Standard | ||

| SSC-AC30A-1L | AC100-110/200-220v | 30A | 1Loop | Standard | ||

| SSC-AC30A-2L | AC100-110/200-220v | 15Ax2 | 2Loop | Standard | ||

| SSC-AC45A-3L | AC100-110/200-220v | 15Ax3 | 3Loop | Large | ||

| SSC-AC60A-1L | AC100-110/200-220v | 60A | 1Loop | Standard | ||

| SSC-AC60A-2L | AC100-110/200-220v | 30Ax2 | 2Loop | Standard | ||

| SSC-AC60A-4L | AC100-110/200-220v | 15Ax4 | 4Loop | Large | ||

| SSC-AC90A-3L | AC100-110/200-220v | 30Ax3 | 3Loop | Large | ||

| SSC-AC120A-2L | AC100-110/200-220v | 60Ax2 | 2Loop | Large | ||

| SSC-AC120A-4L | AC100-110/200-220v | 30Ax4 | 4Loop | Large | ||

*2.Analog input :±10V,±5V,0-10V,0-5V,1-5V,0-20mA,4-20mA

*3.In order to use the water-cooled type halogen heater, water cooling system is required.

*4.HLH of high output type requires a separate cooling air.

*5.Nameplate will be created in designated language as much as possible.

Standard Function

| Memory card data folder | Read the heating data from the memory card, and can edit the tables and graphs in EXCEL. |

|---|---|

| Multi-monitor | Displays the total 8CH of temperature input 4CH and analog input 4CH the trend graph. |

| Multi-temperature setting | Multistage, Sign-curve and Gradient heating setting by a touch panel. |

| Supervisor function | Multiple signal and several heaters coordination heating function. |

| One-shot heating function | Heating time can be established by one shots from the preset temperature arrival value. |

| Temperature input 4CH | K,J,T,E,R,B,N,S,w5Re,w26Re,JPt100,Pt100 4CH |

| Analog input 4CH | ±10V,±5V,0-10V,0-5V,1-5V,0-20mA,4-20mA 4CH |

Optional Function

| TA4 | Temperature and analog multiple input 4CH |

|---|---|

| HL | High-Low Control for rapid-heating or preheating |

| TR | When the trigger is input, and then shift move on to the next set temperature. |

| RC1 | Heating start or stop in the signal from outside |

| RC2 | Specified output voltage in 4-20mA from outside |

| RSP | Specified thermocontroller temp. in 4-20mA |

| PVMON | Monitor, Output 4-20mA signal the temperature of the heating object. |

| SVMON | Monitor, Output 4-20mA signal the temperature of the set volume. |

| RS485 | RS-485 Communication |

| IOT | IOT function |

| ACOUT | Power supply for AC Air cooling fan. |

| DC24 | DC24V power supply cooling fan |

| AirV | Air opening and closing valve |

| OFDT | Air closing valve, heating stop after the cooling timer 5 minutes |

| BO | With heater burnout detection and display. With current limiter. |

| OVH | Over-heat Alarm. (For ABH/DGH□v-□w/□□/+2S type) |

| WP | Cooling water pressure shortage alarm |

| AP | Air Blow Heater and terminal cooling air pressure shortage alarm |

| CFS | Cooling fan stop detection signal processing |

| FPR | Front Protection Rail |

| RPR | Rear Protection Rail |

| Power Cable | Manufacture the specification of the power cable. |

| +α | If user need a function other than the above, please contact us. |

*6.When the to add a function, there is that the external dimensions changes.

General specification

| Power supply | AC100-240v |

|---|---|

| Internal current consumption | 1.6A(except the heater output) |

| Ambient temperature | 0~50℃ (No freezing No condensation No dew) |

| Storage temperature | -10~+60℃ (No freezing No condensation No dew) |

| Use and storage humidity | 35~85%RH (No freezing No condensation No dew) |

| Withstand voltage | AC1500V 1minute Between power supply terminal and input and output terminals |

| Noise resistance | 1500Vp-p Pulse width 1μs,50ns IECstandard compliant 61000,4-2/3/4/6) |

| Insulation resistance | DC500MV- 5MΩ over (Between the power supply terminal and case) |

| Use atmosphere | No Dust, No terribly corrosive gas |

| Use altitude | 2000m or less |

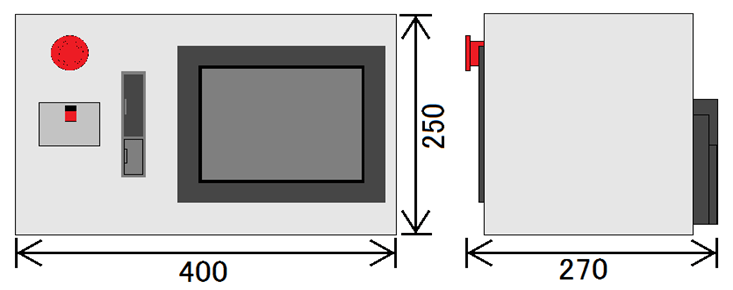

| External dimensions | Height 250mm width 400mm depth 270mm (Standard type) |

| Mass | About 5kg (Standard type) |

Touch panel specification

| Display element | Ultra-high brightness TFT color LCD |

|---|---|

| Display dots Number | VGA 640×480 |

| LCD life | About 5000 hours (Normal temp. and humidity) |

| Backlight life | About 5400 hours (Normal temp. and humidity, Cold-cathode tube can not replaced) |

| Touch switch life | 1million times or more (touch switch actuating force 0.98NT below) |

Memory card specification

| Storage element | CF compact flash card EEPROM |

|---|---|

| File type | CSV |

| Memory capacity | 128MB |

| Number of rewrites | 100,000 or more times |

| Storage capacity | Maximum 128MB, 262144 files |

<< SSC Standard type External dimensions >>

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop