Please sure to use the Air Blow Heater with a rated voltage or less.

Before applying the voltage, make sure that the gas is properly blown out from the hot air outlet. If the supply of compressed gas is stopped while the rated voltage is applied, the heating element will become extremely hot and will burn out in a short time.

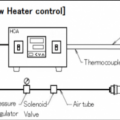

The temperature of the Air Blow Heater can be kept constant by PID control using a temperature controller and SSR.

Our heater controller is the easiest to control the temperature of the Air Blow Heater.

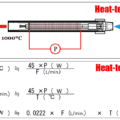

Voltage adjustment (temperature adjustment) method

Use a voltage regulator to adjust the voltage. There are two types of voltage regulators, winding type and semiconductor type.

The winding type is hard to break and can be boosted above the supply voltage. Generally, it can be adjusted from 0 to 130% of the power supply voltage.

The semiconductor type is light and temperature control is easy by using a temperature controller. For semiconductor type, the voltage adjustment range is 0 to 98%.

First, supply compressed gas.

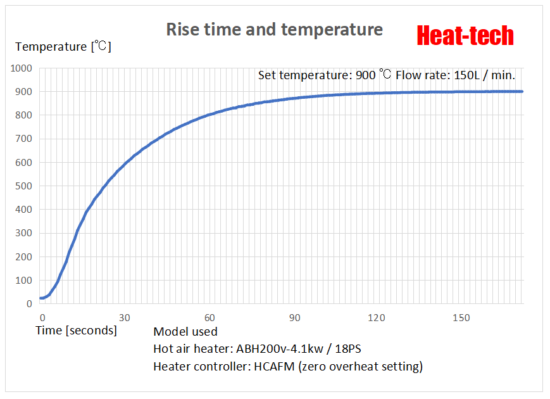

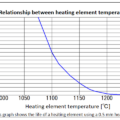

After that, the voltage is increased until the target temperature is reached.

The hot air blow temperature rises with time, but there is a time lag, so it overshoots.

If it overshoots near the rated voltage, it will burn out.

Take time to boost slowly to avoid overshooting.

When it stabilizes, the control is over.

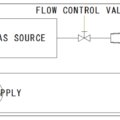

It is important to control the flow rate of the compressed gas because the discharge temperature also changes when the flow rate of the compressed gas fluctuates.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop