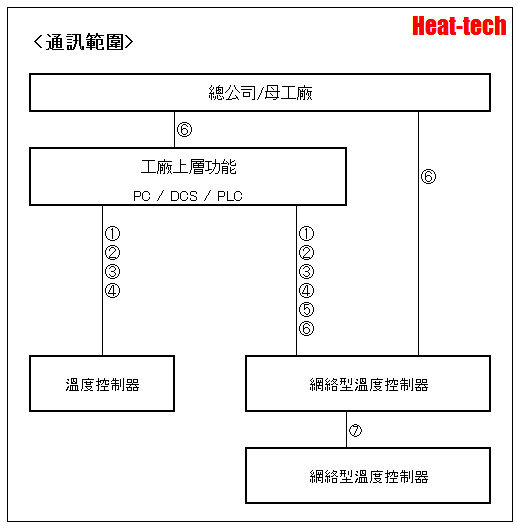

溫度控制器和指示器控制器的通訊功能已逐漸增加和增強。

①最簡單的信號是ON-OFF信號。

正常值或異常值可以通過“ ON-OFF”信號輸出到更高的階。

②接下來出現的是以“ 4-20mA”表示的電流/電壓(模擬)輸出。

可以從ON-OFF二進制值發送多級信息。

③增加了以“ RS-485”表示的時分型數字信號。

這將啟用各種設置,例如電流值,設置值,上限警報,下限警報,加熱器斷開警報,設置值設置,上限警報設置和下限警報設置。

④此外,增加了各種現場網絡功能。

為了適應植物的生長,

1.增加可交流的人數

2.通訊距離的延長

符合目的。

⑤此外,還增加了與上位PLC的“無程序通信”功能。

這是因為PLC的功能已經變得更加複雜,並且可以滿足儀器儀表領域的需求。

⑥增加了以太網通訊功能。

這擴展了從主機(例如母工廠或總部)到工廠或工廠內部的本地PC或PLC的直接和間接通信範圍。

,此外,直到現在,仍使用與主機的垂直網絡,但是現在可以構建水平網絡,以便溫度控制器和指示器控制器可以進行通信和協作。

Azbil的“網絡型溫度/指示器控制器NX”配備了第七代通訊功能。

HEAT-TECH 最佳技術網店

HEAT-TECH 最佳技術網店