Resistance heating has the following features and is most popular for both home and industrial use.

1.Efficient because electric energy becomes 100% heat.

2.Since the amount of heat is equal to the amount of electricity, measurement and management are easy. Temperature control is also accurate.

3. Ordinary electricity can be used as it is.

4. Can be used in a wide temperature range from low to high.

5.Can be used in various atmospheres such as various gases and vacuums.

Types of resistance heating elements

(1) Iron-chromium-aluminum system

When used in an oxidizing atmosphere, such as in the air, aluminum oxide is formed on the surface and some can be used up to 1400℃. High electric resistance, small temperature coefficient and stable. At high temperatures the strength decreases.

(2) Nickel-chromium type

Some products have chromium oxide formed on the surface and can be used up to 1200℃. High electric resistance, small temperature coefficient and stable. It has high strength even at high temperatures, and can be used at temperatures higher than (1) depending on the atmosphere.

(3) Platinum, molybdenum, tantalum, tungsten

Use at high temperatures where (1) and (2) cannot be used. Use is limited to special applications because of the choice of operating atmosphere, high temperature coefficient of electrical resistance, and high price.

(4) Silicon carbide, molybdenum-silicite, carbon

Can be used even at high temperatures where metal heating elements cannot be used. Use is limited to special applications because deformation processing cannot be performed, the use atmosphere is selected, and the temperature coefficient of electric resistance is large.

(5) Ceramic mixed system

The heating element of the ceramic heater is mixed and built into the base ceramics, such as alumina and silicon nitride, and is integrated by simultaneous sintering.

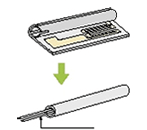

● Comparison of bare heating wire and sheathed heater

Among the resistance heating elements, (1) an iron-chromium-aluminum heating element and (2) a nickel-chromium heating element are the most widely used. In electric stoves and hair dryers that use bare coil, the heating element is directly visible. In contrast, a sheathed heater is one in which a heating element is placed in a metal sheath (pipe) and the space between them is filled with an insulator.

■ Bare heating wire

![]()

lifespan Since the heating element is exposed to the outside air, it becomes shorter depending on the atmosphere such as corrosive gas and dust.

Calorific value Depending on the atmosphere, the heating element corrodes, and the amount of generated heat decreases.

Insulation Since it is not insulated, it is necessary to insulate it with insulators.

Safety If water is applied to the heating element, a short circuit will occur.

Mounting It is necessary to insulate with an insulator so that the heating element does not touch other parts.

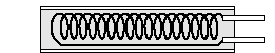

■ Sheathed heater

lifespan Since the heating element is protected by sheath, it has a long life regardless of the atmosphere.

Calorific value The amount of heat generated hardly changes even when used for a long time.

Insulation Since the sheath and the heating element are insulated, they can be mounted directly.

Safety Since the heating element is not exposed, there is no fear of leakage.

Mounting Since the sheath is insulated and can be bent, it is easy to install.

■ Types of ceramic heater

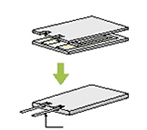

● Plate type

● Bar type

● Cylindrical type

lifespan Resistor is not oxidized, and there is little disconnection and aging

Calorific value High watt density is obtained, heat efficiency is good, and it is possible to bury multiple heating elements.

The temperature rise speed is fast and any temperature distribution can be obtained.

Insulation Direct heating of water, kerosene and metal is possible.

Safety Excellent electrical insulation and voltage resistance. Also, it has excellent oxidation resistance and chemical resistance.

Mounting Can be designed freely

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop