INDEX

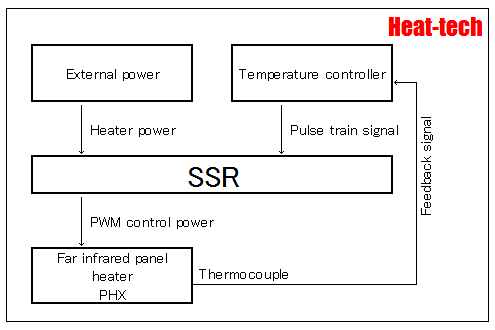

SSR is a solid state relay made of semiconductor.

■ Features of mechanical relay

① Voltage output and voltage output can be controlled simultaneously.

② Both current and voltage can be controlled simultaneously with current output.

③ AC output and DC output can be controlled simultaneously.

④ DC output allows simultaneous control of both AC and DC

⑤ Almost no effect from noise.

⑥ Noise can be cut off by insulating with coil.

⑦ High heat resistance.

⑧ A self-holding circuit can be easily assembled.

There are many excellent points such as.

■ Disadvantages of mechanical relay

① A bypass circuit must be provided to generate induced electromotive force in the coil.

② Since it operates with a coil, there is a delay from input to output.

③ Since the contacts are leaf springs, there is a life due to metal fatigue. (Mechanical life)

④ An arc is generated at the contact and the contact deteriorates. (Electrical life)

⑤ An arc may be generated at the contact and noise may occur.

There are disadvantages such as.

■ Features of SSR

Solid state relays have solved the problem of mechanical relays on heater controls.

① The hysteresis of semiconductor circuits is much smaller than that of coils.

② Since no induced electromotive force is generated, the input circuit is simplified.

③ No noise countermeasure is required because there is no contact

④ Long life due to no contact.

There are many benefits.

■ Disadvantages of SSR

① A semiconductor element always has a voltage drop (ON resistance or forward voltage drop), and when the load current increases, heat generation cannot be ignored.

② With a load current of about 5A, the amount of heat generated is at most about 10W, so simple heat radiation is sufficient. However, when opening and closing motors and heaters, heat generation cannot be ignored due to the current value of 50A or 100A, and forced air cooling or a large heat sink is required.

■ Application of SSR

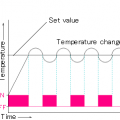

SSR is mainly used in a control method called PWM.

PWM (Pulse Width Modulation) is a method of controlling power by high-speed switching.

From the input of constant voltage, a constant cycle of high-speed pulse train on and off is created, and the on-time width (duty ratio) is changed.

The control method that regards the duty ratio as a voltage ratio is called PWM control.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop