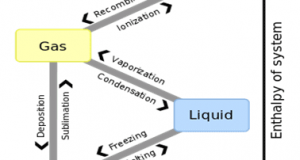

If alcoholic disinfection is carried out before injecting, when alcohol evaporates, he will have a cold feeling to because heat is taken. In order for a liquid to turn into gas, energy is required and this energy is called evaporation ...

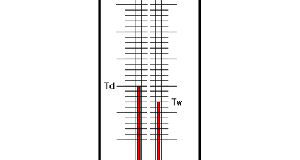

Read More »2-7.Psychrometer and Hygrometer

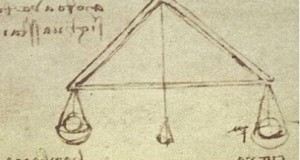

2-7-1.Spirits of Dry and Wet Líu Ān (Chinese: 劉安, c.179 – 122 BC) was a Chinese king and advisor to his nephew, Emperor Wu of Han (武帝). The old days of more than 2000 years from now, Concept of humidity ...

Read More »2-6.Relationship of absolute humidity and the relative humidity

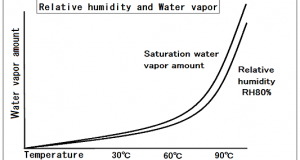

We have explained the relative humidity and absolute humidity to 2-5 from 2-1. Let’s check again here. Quantity the water of which exists in the air with absolute humidity Even if it heats air, since the weight of the water ...

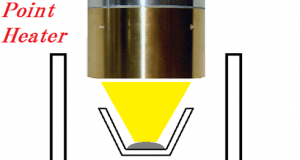

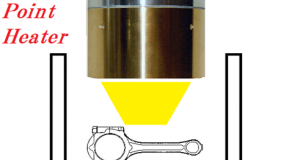

Read More »No.20 Synthesis of ceramics

[ Problem Point ] It was in trouble without a heater that can be synthesized ceramics in a short period of time. [ ⇒Kaizen Point ] Ceramics is heated at a high output Halogen Point Heater of 3kW. Ceramics was ...

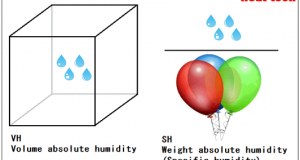

Read More »2-5.Absolute humidity

Absolute humidity Generally, if it is only called “Humidity”, “Relative Humidity =RH” will be pointed out, but it is convenient to use the absolute humidity from which a value does not change in a design or control of a drier ...

Read More »2-4.Relative humidity RH

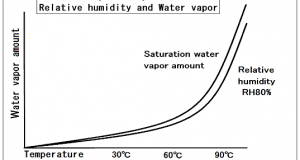

Relative humidity RH Relative humidity is the ratio of the partial pressure of water vapor in an air-water mixture to the saturated vapor pressure of water at a prescribed temperature. The relative humidity of air depends on temperature and the ...

Read More »No.19 Performance testing of heat-resisting metal

[ Problem Point ] It is in trouble if there is no heater in a high temperature in a short period of time. [ ⇒Kaizen Point ] Heat-resisting metal is heated at a high output Halogen Point Heater of 3kW. ...

Read More »Heat-tech News Letter – Vol. 004

■□■━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━■ □■ Heat-tech News Letter – Vol. 004 2014-04-15 ■━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━■□■ □ INDEX ■1. Guidance of the new product ■2. Guidance of new applications ■3. Support Information ■4. Editor’s note ┏━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━┓ ■1. Guidance of the new product ┗━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━┛ 1-1) [ Air ...

Read More »Heating to 1000 ℃ the air by the Air Blow Heater

This video is a demonstration that is heating to 1000 ℃ the air by the Air Blow Heater.

Read More »2-3.Ask for saturation water vapor pressure

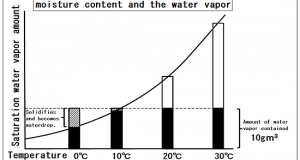

The saturation water vapor amount is the representation of g in the mass of water vapor that can be present in the space of 1m3. Absolute humidity volume, saturation water vapor density is also known as, aka. Saturation water vapor ...

Read More »No.18 Point heating and drying of the sealant

[ Problem Point ] In the winter, it is in trouble sealant without drying out. [ ⇒Kaizen Point ] Dry by heating with a Halogen Point Heater. Easy dried.

Read More »10. The main materials Specific gravity,specific heat and thermal conductivity

Thermal properties of various substances Material-Metal Reference temperature [℃] Density [g/cm3] Specific heat [J/g ℃] Thermal conductivity [W/m K] Zinc 20 7.13 0.383 113 Aluminum 20 2.7 0.9 204 Aluminum oxide 20 3.9 0.875 30 Duralumin 20 2.79 0.84 164 ...

Read More »2-2.There is a limit to the water vapor contained in the air

There is a limit to the amount of water vapor that air can contain. Within the air, water movement may become gas (vapor) from a liquid, that or become liquid from gas (vapor) has been constantly repeated. The temperature that ...

Read More »9. Attention in the infrared rays use (Q&A)

(Q) Can heat in the far-infrared rays metal? (A) Since there is a lot of metal electrons, it reflects the electromagnetic waves (far-infrared rays) in general. The good conductivity metal such as gold and aluminum, it is hard to heating ...

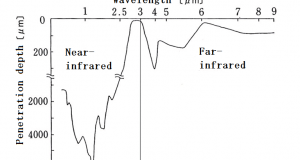

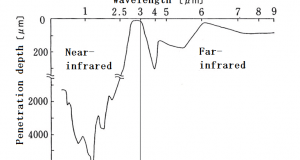

Read More »8. Comparison of far-infrared rays and near-infrared rays

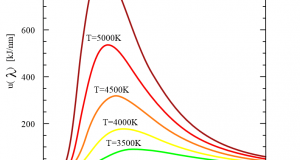

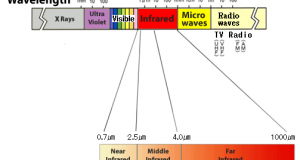

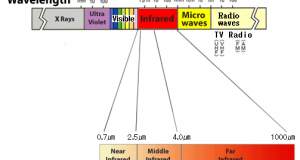

(1) Infrared Rays are subdivided into several scheme. ISO 20473 specifies the following scheme: Designation Abbreviation Wavelength Near-Infrared NIR 0.78–3 µm Mid-Infrared MIR 3–50 µm Far-Infrared FIR 50–1000 µm (2) Difference in frequency = The difference between the heating capacity By “Wien’s displacement ...

Read More »7. Generation of far-infrared rays

The method of heating the ceramic to make a far-infrared artificially is common. The fine ceramics of an alumina system or a zirconium system are used well. Wavelength and the emittance change by a kind and the heating temperature of ...

Read More »2-1.What is the humidity?

The Chapter 1 focused on moisture inside material. The Chapter 2 focuses on the moisture emitted in the form of vapor into the air. Definition of the humidity Of humidity, it is a representation of a number the wetness in ...

Read More »6. Absorption rate of infrared rays

【 Infrared Absorption Rate 】 Please confirm the index of absorption of infrared rays in this table. The material absorbed by about 0.5 = 50% or more is suitable for the infrared heating.

Read More »5. 4 basic laws about radiation

1.Planck Radiation Law Max Karl Ernst Ludwig Planck, FRS (23 April 1858 – 4 October 1947) Planck’s law describes the electromagnetic radiation emitted by a black body in thermal equilibrium at a definite temperature. The law is named after Max ...

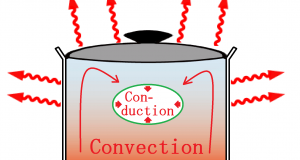

Read More »4. About heating

The thermal energy transfer from higher temperature to lower temperature. Transfer of the thermal energy , there are three principles, Conduction, Convection, and Radiation. In an actual situation, transfer of the thermal energy is performed in the form these three ...

Read More »3. Type of the infrared rays

Infrared Rays are subdivided into several scheme. ISO 20473 specifies the following scheme: Designation Abbreviation Wavelength Near-Infrared NIR 0.78–3 µm Mid-Infrared MIR 3–50 µm Far-Infrared FIR 50–1000 µm The International Commission on Illumination (CIE) recommended the division of infrared radiation into the following ...

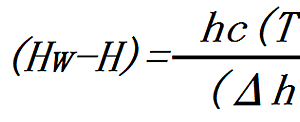

Read More »1-9.How to expressions the constant drying period

Constant drying period is the mass of the water which evaporates per unit time and unit surface area. The unit is kg/s㎡. Constant drying rate Jc is expressed by the following equation. kH: Mass transfer coefficient Hw: Saturated absolute humidity ...

Read More »2. About infrared rays

Although it is not visible, because the light with the power which warms a thing existed “outside red”, it was named “infrared rays.” Infrared rays are the same “Electromagnetic waves” as “X-rays”, “Ultraviolet rays”, “Visible light”, “Microwave”, “Radiofrequency wave”, etc. ...

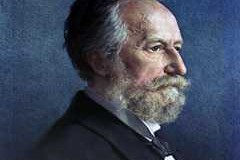

Read More »1. The discovery of the infrared rays

<Science of the Infrared rays -INDEX- > 1. The discovery of the infrared rays 2. About infrared rays 3. Type of the infrared rays 4. About heating 5. 4 basic laws about radiation 6. Absorption rate of infrared rays 7. ...

Read More »1-8.Why is the constant drying period. – Moisture movement in wet material.

Inside moisture material, movement of water (liquid) mainly takes place from the point that moisture content is high to a low point on the surface from an inside in accordance with a slope. There is capillary suction force action, osmotic ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop