INDEX

- ■ Auto tuning function

- ● Step response method

- ● Limit sensitivity method

- ● Limit cycle method

- ■ Self-tuning function

- ● Calculation of PID constant by self-tuning

- ● About evaluation of target value response

- ● When PID constants are changed by self-tuning

- ● Calculation of PID constant by self-tuning during vibration

- ● Timing when PID constant is changed by self-tuning during vibration

- ■ When using the self-tuning function

- ■ What is the difference between “auto tuning” and “self tuning”?

- ● Basic operation

- ● Calculation results

- ● Execution of tuning

- ● Response during tuning

- ● When the characteristics of the controlled object fluctuate

In order to perform good control with a PID controller, it is necessary to set an appropriate PID constant according to the control target.

Adjusting the PID constants is called “tuning”. When analog controllers were at their peak, operators tuned them manually.

Finding the optimal value of PID required a lot of experience and knowledge.

When the controller shifts from an analog type to a digital type and a microcomputer is built in, an “auto-tuning function” that automatically calculates and sets PID constants according to the control target comes to be installed. It has a self-tuning function that is more intelligent than auto-tuning.

■ Auto tuning function

Numerical values and combinations of PID constants for temperature control differ depending on the characteristics of the control target. Conventionally, various methods have been proposed and implemented to derive these PID constants from the temperature waveform actually controlled. The method of using these methods to derive PID constants that allow appropriate control of various controlled objects is called auto-tuning, and typical methods include the step response method, the limit sensitivity method, and the limit cycle method.

● Step response method

Set the settings to the values user use most often. Outputs 100% of the operation amount in steps, measures the maximum temperature gradient (R) and dead time (L), and calculates the PID constant from the values of R and L.

● Limit sensitivity method

Proportional operation starts from the start time (point A). The width of the proportional band is gradually reduced to generate temperature oscillation. The PID constant is calculated from the value of the proportional band and the period of vibration (T).

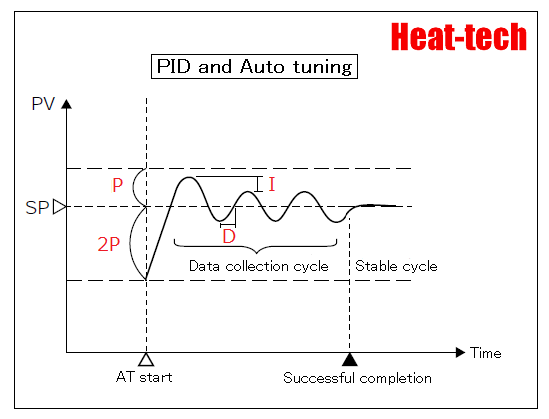

● Limit cycle method

ON / OFF operation starts from the start time (point A). The PID constant is calculated from the value of the hunting period (T) and amplitude (D) generated thereby.

■ Self-tuning function

The self-tuning function is automatically executed when the operation during daily operation or when the control condition is not good, and calculates and sets the PID constant.

● [Power on, change target value, STOP → RUN] ● [Control response vibrated]

①Supply power, change target value, self-tuning when changing STOP → RUN

The power supply is turned on, the target value is changed, and the target value response waveform at STOP → RUNSTOP is observed, and the PID constant is calculated automatically.

The feature is that the target value response waveform is evaluated by “waveform observation processing” at the same time as “calculation of PID constant”, and the PID constant calculated only when the response is not good is set.

(If the target value response waveform is good, the calculated PID constant is not set.)

Therefore, the response when changing the target value depends on the PID constant set when changing the target value.

(At this time, if the target value response is not good, the PID parameter is corrected by the start-up AT, so a good target value response can be obtained from the next change of the target value.)

● Calculation of PID constant by self-tuning

The self-tuning function calculates the PID constant from the response of the amount of observation from when the target value is changed or when the power is turned on until the target value is stabilized.

The calculated PID constant is set in the controller only when the response to the target value is poor.

● About evaluation of target value response

Evaluate “response speed”, “overshoot amount” and “attenuation amount”.

● When PID constants are changed by self-tuning

Set a new PID constant at the timing when the response is evaluated as “response failure”.

②Self-tuning when control response vibrates

This is a self-tuning function that automatically corrects PID parameters so that vibration converges when the control response becomes oscillating due to changes in the characteristics of the controlled object or changes in operating conditions.

● Calculation of PID constant by self-tuning during vibration

The self-tuning function calculates the PID constant from the response waveform (vibration response) of the observed quantity.

● Timing when PID constant is changed by self-tuning during vibration

A new PID constant is set when it is determined that the observed quantity is oscillating continuously and the damping rate of the oscillation is not good.

■ When using the self-tuning function

● When turning on the controller power, turn on the power to be controlled, such as the heater power supply, in advance.

The self-tuning function for “when power is turned on and target value is changed” calculates the PID constant from the response of the amount of observation from when the target value is changed or when the power is turned on until the target value is stabilized.

For this reason, if the power of the control object such as the heater power is not turned on when the controller is turned on, the [measured response] and the [response] will be different. May be calculated and set.

● Do not use the self-tuning function for the following control objects because inappropriate PID constants may be set by self-tuning.

① A controlled object in which a large disturbance (uncontrollable disturbance) enters periodically

(Example: Mold temperature control of injection molding machine, hot plate temperature control of semiconductor manufacturing equipment)

② Control target with very strong mutual interference

However, there is no problem if the control target does not have a large mutual interference, such as temperature control of the extruder cylinder.

The self-tuning function at the time of “vibration” is such that when a vibration occurs due to a mismatch of PID constants (P: small, I: small, D: large, etc.), the gain of the PID constant is appropriately loosened so that the vibration is settled. Works.

Accordingly, the same operation is performed for a response that appears to vibrate due to the influence of a periodic disturbance such as the above ① and ②. As a result, the PID constant is loosely corrected by self-tuning. I will.

Generally, in order to suppress the effects of the above (1), (2), etc., it is necessary to modify the PID constants closely. Therefore, self-tuning during vibration does not calculate the optimal constants under these conditions.

Also, when the self-tuning function is operated under the above conditions, the response to the target value change or disturbance becomes slow because the PID constant is set loosely.

■ What is the difference between “auto tuning” and “self tuning”?

* The auto tuning function is indicated as “AT” and the self tuning function is indicated as “ST”.

● Basic operation

(AT) Calculate and set PID constant from response of on / off control

(ST) The controller itself observes the control response without any special operation, and changes the PID constant to an appropriate value.

● Calculation results

(AT) Optimum PID value can be obtained by one training

(ST) One tuning may not converge to the optimal PID constant value

● Execution of tuning

(AT) It is necessary to manually instruct execution of auto tuning.

(ST) Automatically executed by controller

(ST) Not executed unless the control state changes, such as when the target value changes or the response becomes oscillatory.

● Response during tuning

(AT) The control is disturbed due to on / off control.

(ST) Since the on / off control is not performed, the control is not disturbed.

● When the characteristics of the controlled object fluctuate

(AT) It is necessary to execute auto tuning again

(ST) The PID constant is automatically set by the controller

The self-tuning function differs from the auto-tuning function in that it observes the normal control response waveform and automatically calculates and sets the PID constant.

■ Conclusion

(1) For the first tuning at the start-up of the device, use “auto tuning” which can obtain a good constant at one time, and use “self tuning” for the characteristic fluctuation after “auto tuning”. .

(2) There are conditions where auto tuning cannot be used.

In these cases, do not use auto tuning, but perform manual adjustment.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop