INDEX

Measures against inrush current of halogen heater

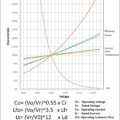

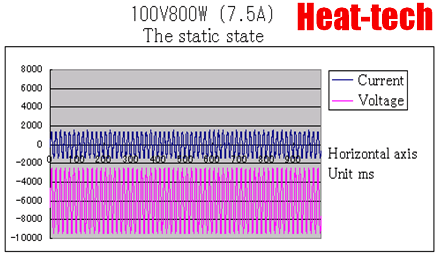

The electrical resistance of the halogen heater when it is off is 0.2 ~ 0.7Ω.

In other words, it is easy for a large inrush current to flow momentarily when it is lit.

The inrush current is directly linked to the lamp lifespan. When the heater is turned on, the power supply voltage should be slowed up as much as possible.

The inrush current is proportional to the rated current value of the heater, but it is necessary to slow down the power supply voltage of the heater regardless of the magnitude of the current.

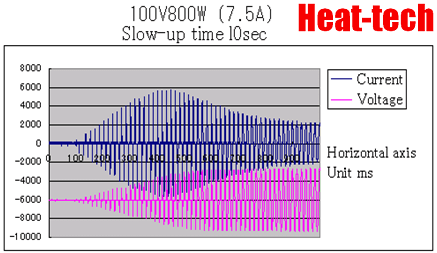

The slow-up time requires at least 1 second for a small DC type heaters and at least 2 seconds for a large AC type heaters.

For the reason, please be sure to install an inrush current countermeasure device.

| Throw up | Inrush current | Correction value | |||

|---|---|---|---|---|---|

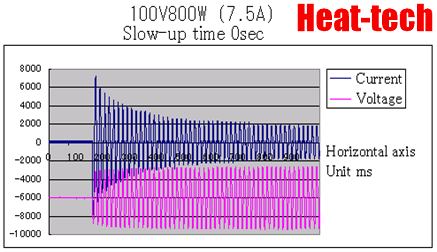

| 0sec | 5.6times | 7.0times | |||

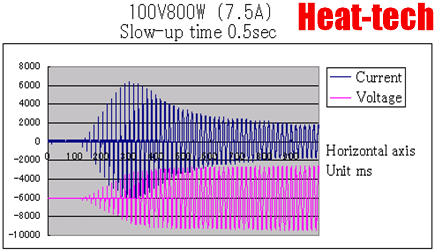

| 0.5sec | 4.6times | 5.4times | |||

| 1sec | 4.1times | 5.2times |

The inrush current correction value is a calculated value assuming that the power supply resistance is 0Ω.The first cycle of inrush current at 0 seconds of slow-up is a sine wave.

After that, the current limit of the power regulator starts to operate, and the current limit state is entered from the latter half of the third cycle.

Since the inrush current at the time of slow-up is a phase-controlled waveform,

The effective value ratio of the inrush current is about 40% of the above (assuming a triangular waveform).

Conclusion

The inrush current allowed for the power regulator is about 3 times the rated current x about 2 seconds.

When the rated current of the power regulator is 30A

Slow up 0 seconds Calculated with peak current value → Heaters up to 30×3 / 7 = 12.9A can be used

Slow up 0.5 seconds, calculated by peak current value → Heaters up to 30×3 / 5.4 = 16.6A can be used

Slow up 1.0 seconds, calculated by peak current value → Heaters up to 30×3 / 5.2 = 17.3A can be used

Calculated by effective value → Heaters up to 30×3 / (5.2 * 04) = 43.2A can be used.

“Is it okay to consider the inrush current as an effective value?

It is delicate considering the cutoff characteristics of fuses and thyristor protectors. ”

It is necessary to test whether the fuse and thyristor protector work on the experimental aircraft.

In addition, overcurrent (inrush current) may be energized by the power supply device and the breaker may work to cut off the current.

Inexpensive direct current power supplies may be protected by “Fold-back Type Drooping Characteristic” of overcurrent protection (OCP).

It may not be usable as a power source for halogen heaters.

This is because the inrush current at the time of lighting enters the area of ”Fold-back Type Drooping Characteristic” and the output voltage does not rise.

It can be used if it has “Constant current voltage droping characteristics”. please be sure to check with the manufacturer before using.

Phase control is generally used to control the AC power supply.

In phase control, the output voltage can be adjusted continuously, so inrush current can be prevented.

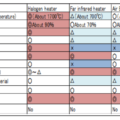

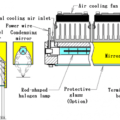

About cooling of halogen heater

If user heat it at a high temperature, please be sure to cool it because it will affect the damage of the seal part of the halogen lamp and the deterioration of the main body and will involve to the lifespan. It is recommended that the controller be equipped with safety measures such as shutting off the heater if cooling is cut off.

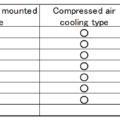

There are three types of cooling methods for halogen heaters: a cooling fan mounted type, a compressed air cooling type, and a water cooling type.

The following are the characteristics of each cooling method.

(1) Cooling fan mounted type

It can be used just by the heater controller.

Operate at the rated voltage of the cooling fan. Use is assumed at room temperature.

(2) Compressed air cooling type

It requires a heater controller and an air compressor, but it is small.

Please use the air flow rate at about 20 L/min per 100W of heater power.

The pressure is assumed to be about 0.7 to 0.9MPa , which is the general maximum pressure.

(3) Water Cooling type

A heater controller and chiller (cooling water) are required, but it can also be used in a vacuum container.

The minimum flow rate of cooling water is 0.5L/min per 1kW of heater power.

From the viewpoint of safety, we recommend at least twice the minimum flow rate.

The cooling water temperature is assumed to be about 15 ℃. If the cooling water is too low, there is a risk of electric leakage due to condensation or water droplets generated from the condensation. It is assumed that the pressure will be about 200kPa or less. If it is over 300kPa, please contact us.

About the voltage used by the halogen heater

If the voltage exceeds the rated voltage, the filament will be broken and the lifespan will be shortened extremely.

The lamp lifespan will be improved if the lamp is used at the lowest possible voltage within the range that meets the required heating conditions.

It was A 10% voltage drop will extend the lifespan by about 3 times, and a 10% voltage rise will reduce the lifespan by about 1/3.

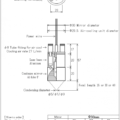

About the mounting direction of the halogen heater

The point heater can be used at any angle, but the line heater should be used horizontally in the longitudinal direction. This is because installing the line heater vertically puts a load on the filament of the lamp.

When installing the line heater vertically, install a vertical lamp.

Do not apply vibration or shock. If the impact is strong, it may damage the quartz tube or break the filament.

Even if the filament has no visible evidence of damage, it may be damaged. In this case, even if the effective value is less than the rated voltage, a high voltage is applied momentarily, which may cause dielectric breakdown in the lamp, resulting in disconnection or explosion.

About cleaning the halogen heater

Condensing mirrors are the most important and maintenance-intensive part of halogen heaters.

If the Condensing mirror becomes dirty due to smoke or scattered matter generated from the object to be heated, the reflectance will be significantly reduced.

To prevent dirt, install a protective glass in front of the condensing mirror, and clean and replace it in a timely manner.

There is also a method of sealing the inside with protective glass and filling the inside of the condensing mirror with positive pressure.

In the case of the water-cooled type, foreign matter may accumulate in the cooling path depending on the water quality.

In addition, Aluminium may combine with air and oxygen to accumulate white Aluminium hydroxide.

Please check the cooling path as appropriate and keep it clean.

About lamp replacement

All replacement lamps for point heaters have a base. Since they have a base, they can be replaced simply by attaching and detaching the condensing mirror, so they can be installed with high reproducibility and high accuracy.

Since it comes with a replacement lamp line for the line heater, it can also be replaced by simply attaching and detaching the terminal, so it can be installed with high reproducibility and high accuracy.

Please note that it affects the reflectance, so replace it so that the lamp and Condensing mirror are not dirty.

Also, if user touch the lamp with user bare hands, the sebum of user hands will remain on the glass plane, causing damage during lighting and a decrease in heating efficiency. please be sure to wear protective equipment before replacing. If fingerprints etc. adhere to it, degrees it with a cloth coated with alcohol.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop