In the ON-OFF control, when the heating output (operating amount) is 0% or 100%, the control result overshoots due to the effect of detection and reaction delay, and cycling is repeated.

Cycling is inevitable with ON-OFF control because it performs binary operation of 0% and 100%.

Therefore, as a method of improving the cycling phenomenon of ON-OFF control, more values of the operation variables are taken. This is called multi-value control.

In multi-value control, the more the number of values, the smoother the control should be.

And the limit is to continuously change the value of the manipulated variable.

Changes the value of the manipulated variable in proportion to the deviation

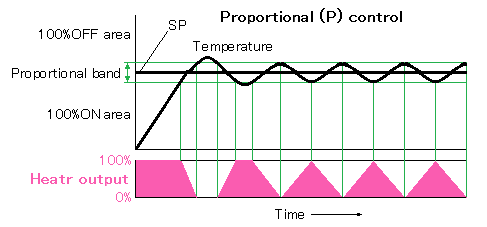

In addition to the two operating states of 0% and 100%, according to the temperature change within the range of the proportional band, the operation amount is reduced when approaching the target value to suppress the rapid change in temperature.

Proportional control was designed to continuously change between 0 and 100%.

By adopting this method, it is possible to obtain stable control results even for moving controlled objects.

As shown in the figure, the proportional band is the width of the change in the control amount (temperature, pressure, etc.) required to change the manipulated variable stepwise from 0 to 100%.

For example, if the set value is 100℃ proportional width ± 10%, the proportional range is 90 ℃ to 110℃.

0~90℃→100%ON

91℃→95%0N-5%OFF

92℃→90%0N-10%OFF

93℃→85%0N-15%OFF

94℃→80%0N-20%OFF

95℃→75%0N-25%OFF

96℃→70%0N-30%OFF

97℃→65%0N-35%OFF

98℃→60%0N-40%OFF

99℃→55%0N-45%OFF

100℃→50%0N-50%OFF

101℃→45%0N-55%OFF

102℃→40%0N-60%OFF

103℃→35%0N-65%OFF

104℃→30%0N-70%OFF

105℃→25%0N-75%OFF

106℃→20%0N-80%OFF

107℃→15%0N-75%OFF

108℃→10%0N-90%OFF

109℃→5%0N-95%OFF

110℃→100%OFF

(The ON-OFF ratio of 50:50 at a set value of 100℃ is a device designed in such a way, and a good device that has achieved the design intention.) Even with this device, the set value can be 150℃ (The ON-OFF ratio changes.)

If the proportional band is set to be narrow, the manipulated variable will change greatly even if the control value changes slightly. Therefore, the sensitivity of the manipulated variable increases, but the stability of the control result deteriorates. If the proportional band is extremely narrowed, the control result will be similar to the ON-OFF control. Conversely, if the proportional band is widened, the ratio of the manipulated variable to the change in the control variable will decrease. Thus, the sensitivity of the manipulated variable decreases, but the stability of the control result increases. Therefore, it is important to adjust the width of the proportional band for optimal control.

For example, if the product accuracy is ± 10℃, if the set value is changed from 100℃ to 200℃, and if the proportional band is ± 10%, then at 100℃ it will be ± 10℃, but if it becomes 200 ℃, then ± 20 ℃. is. The correct setting must be reset to ± 10℃ of ± 5%.

We have discussed ON-OFF control and proportional control as frequently used control methods.

Which control method should be used depends on the stability of the control result to be obtained. Use ON-OFF control when the stability of the control result is not required so much, and use proportional control to obtain a more stable control result. Is common.

Proportional control eliminates steady-state cycling, but leaves a deviation after settling down.

This steady deviation is called an offset.

Offset is an inevitable phenomenon in proportional control.

The offset value differs depending on the control target.

If the value of the offset is small and within the allowable range, proportional control becomes practical.

Since stable operation conditions are required for resource and energy saving and uniform and improved quality, proportional control is used in most equipment and factories.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop